SCREW COMPRESSOR PRINCIPLE AND ADVANTAGES AND DISADVANTAGES

- 2023/07/15

- 778

First, the working principle of screw type refrigeration compressor

Screw refrigeration compressor is a new type of high speed compressor. The principle of gas pressure improvement of screw compressor is the same as that of piston compressor, which belongs to volumetric compression. At present, the general use of twin-screw compressors, twin-screw compressors use two screws meshing each other to do relative rotational motion to compress gas. With the rapid development of China's cold storage industry, and the improvement of processing means, screw refrigeration compressors have had great development in recent years, cold storage increasingly tends to be large, the variety of units is increasing, the scope of use is expanding, and to expand to different application fields. It has now developed into one of the main forms of refrigeration compressors.

Driven by the motor, the active rotor rotates with the motor, and the engaged driven rotor also follows the opposite direction. In the rotor movement, when a pair of meshing grooves of the active rotor and the driven rotor are connected with the suction pipe, the full suction is carried out; When the rotor continues to rotate, the pair of suction grooves leave the suction orifice on the suction end face, and the gas in the tooth groove closed by the suction and exhaust end seat is isolated by the outside of the housing and begins to be compressed; The active and driven rotors continue to rotate, and the tooth peak of the active rotor continuously fills the tooth valley of the driven rotor (that is, the groove), similarly, the tooth peak of the driven rotor constantly fills the tooth valley of the corresponding active rotor, so that the groove volume of the respective rotors is gradually reduced, and the gas in the groove is gradually compressed.

When the gas pressure reaches the specified value, the rotor turns to the position where the groove is connected with the exhaust port to discharge the gas. In such a continuous operation, the refrigerant is continuously compressed and discharged from the screw compressor. A large amount of oil is injected into the screw refrigeration compressor during the compression process to take away the heat generated during the compression process, and the oil film is used to seal the gap between the Yin and Yang rotors and the gap between the rotor and the cylinder, so that the internal leakage loss is reduced. In addition, the Yin and Yang rotors are lubricated, and the noise is reduced. The screw type refrigeration compressor has a sliding valve type energy regulation device, which can be stepless adjustment of the load.

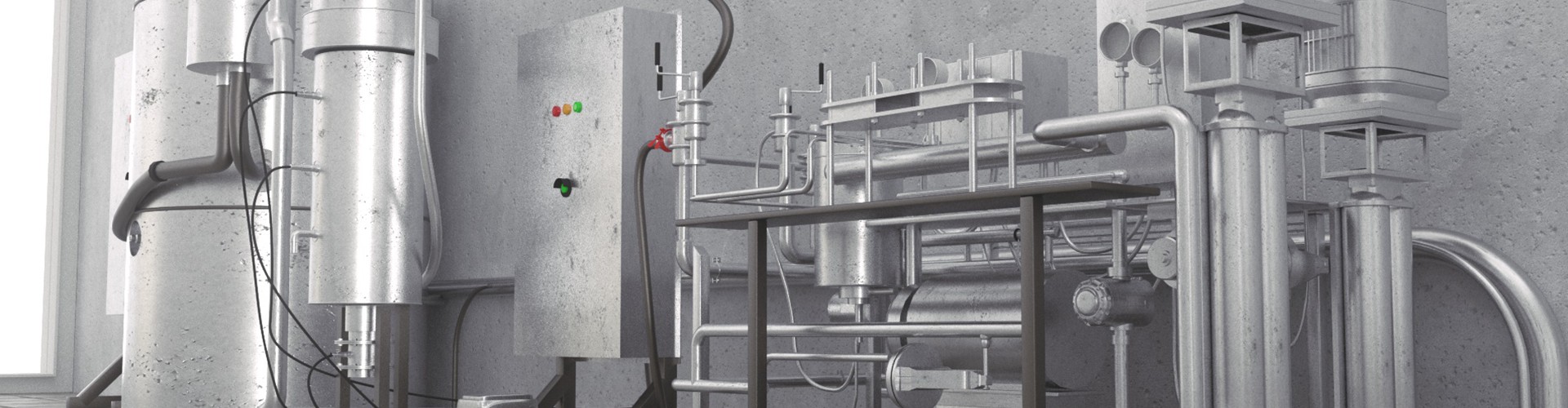

Screw refrigerator

Two, screw type refrigeration compressor advantages and disadvantages

The advantages and disadvantages of screw type refrigeration compressor are quite obvious compared with piston type refrigeration compressor.

1. Major advantages

1) Easy management. There is no piston compressor with suction, exhaust valve, piston, piston ring, cylinder liner and other vulnerable parts, easy maintenance. Smooth and reliable operation, easy to achieve remote control and automation.

2) High speed, good economic performance. Screw compressor is rotary machinery, because there is no suction and exhaust valve, so the speed can be increased, usually the speed is 1500-3000/min, generally higher than the piston compressor speed, thus improving the economic indicators.

3) Small size and light weight. Due to the high speed, when the exhaust volume is the same, the machine has a small size, compact structure, light weight, less metal consumption and small footprint.

4) Small foundation. Because the screw compressor does not have the mass inertia force of the piston compressor, the dynamic balance performance is good, so the foundation can be made very small.

5) Single refrigeration capacity is large. At present, the cooling capacity of domestic screw refrigeration compressor series is 9~2300kW/h, which can meet the different needs of production.

6) Strong operation adaptability. Can be applied to a variety of refrigerants, high volumetric efficiency. Even at low evaporation temperature and high compression ratio, it still has good performance. Since there is no clearance volume, the volumetric efficiency is much higher than that of the piston type.

7) Low exhaust temperature. Using injection cooling, the exhaust temperature is lower than reciprocating, so single-stage compression can still be used at a higher compression ratio. When the evaporation temperature is -40 ° C, the discharge temperature is less than or equal to 90 ° C, which is beneficial to the operation of the parts.

8) Simple structure. The structure is relatively simple, the number of parts is small, the operation cycle is long, the number of maintenance is less, and the processing time is saved.

9) Continuous stepless regulation. Since the most widely used is the use of slide valve for energy regulation, the cooling capacity can be stepless adjusted in the energy range of 10% to 100% to achieve continuous stepless regulation.

10) Long operating life. Because the machine has few wearing parts and reliable usability, the operation cycle is long. Generally, the machine runs for 3000~50000h before being repaired once.

11) No liquid blow risk. Due to the characteristics of the structure, screw compressor is not sensitive to wet stroke, it can allow wet steam or a small amount of liquid refrigerant into the body, no liquid strike risk.

Parallel screw machine

2. Major weaknesses

1) Rotor processing is difficult. Rotor machining precision requirements are high, processing is more difficult, need special equipment.

2) The auxiliary equipment is huge. For the oil-injected screw compressor, in order to separate the lubricating oil in the exhaust, it is necessary to have a large volume, complex structure, high efficiency oil separator and oil return device.

3) Loud noise. Because the rotor tooth groove periodically passes through the suction and exhaust orifice at high speed, and the leakage through the gap, the noise is large. Generally, if the equipment room is set up with screw refrigeration compression, the equipment room does not rely on the main library or other workshops, it is best to leave other buildings to be arranged separately, and the noise reduction is relatively good. It is best to set the noise separation between the machine room and the equipment control room to reduce the noise interference to the operator.

Screw refrigeration compressors are currently used in freon cold storage and single - and two-stage (-40 ° C) systems. In large and medium-sized (cooling capacity above 350kW/h) occasions, the advantages are more prominent.