Principle of piston compressor

- 2023/07/18

- 705

First, the working principle of piston compressor

When the crankshaft of the piston compressor rotates, the piston does reciprocating movement through the transmission of the connecting rod, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston will change periodically. When the piston of the piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases, at this time, the gas is pushed along the intake pipe and enters the cylinder, until the working volume changes to **, the intake valve is closed; When the piston of the piston compressor moves in reverse, the working volume in the cylinder is reduced, and the gas pressure is increased. When the pressure in the cylinder reaches and is slightly higher than the exhaust pressure, the exhaust valve is opened, and the gas is discharged from the cylinder until the piston moves to the limit position, the exhaust valve is closed. When the piston of the piston compressor moves in reverse again, the above process is repeated. In short, the crankshaft of the piston compressor rotates once, the piston reciprocates once, and the process of intake, compression and exhaust are successively realized in the cylinder, that is, a working cycle is completed.

Two, piston compressor refrigeration process

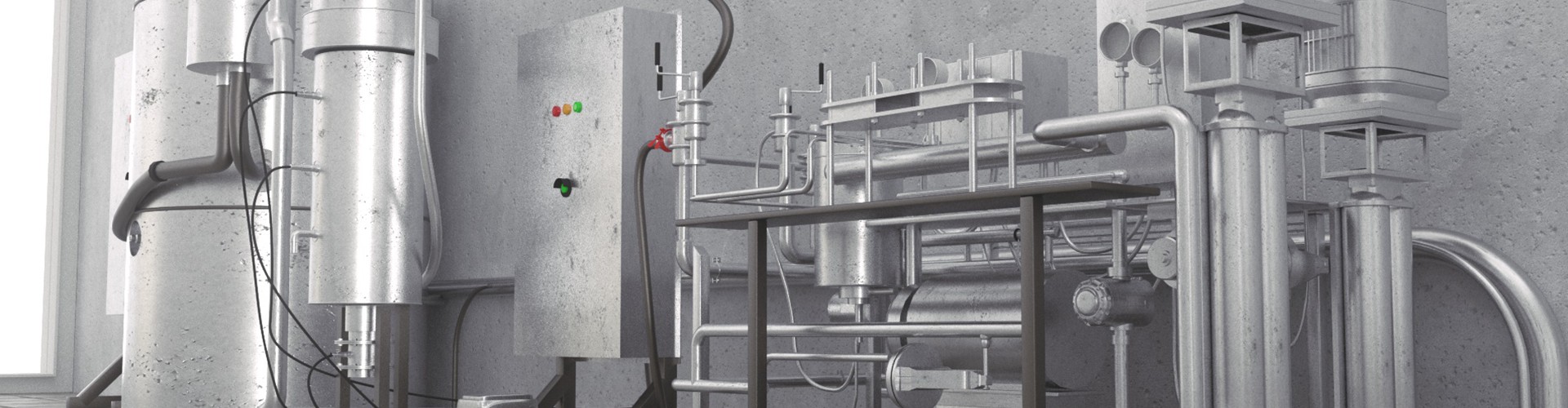

The refrigeration process is carried out in the circulatory closed system composed of ammonia compressor, cooler, regulating valve, evaporator, etc. The ammonia liquid enters the evaporator after reducing the pressure through the regulating valve, absorbs the heat of the cooled medium and evaporates, so that the temperature of the medium is reduced to achieve the purpose of refrigeration; The evaporated ammonia gas is sucked back by the compressor, compressed and discharged into the cooler, so that the ammonia gas is cooled and condensed into ammonia liquid, and then, through the regulator and then into the evaporator evaporation, so repeated cycle to achieve the purpose of refrigeration.

Three, the advantages of piston compressor

1, the applicable pressure range of piston compressor is wide, regardless of the flow rate, can reach the required pressure;

2, piston compressor thermal efficiency is high, less power consumption per unit;

3, strong adaptability, that is, the exhaust range is wide, and is not affected by the pressure level, can adapt to the wider pressure range and cooling capacity requirements;

4, the piston compressor has low material requirements, multi-purpose ordinary steel materials, easier processing, and lower cost;

5, the piston compressor technology is more mature, the production and use of accumulated rich experience;

6, the device system of piston compressor is relatively simple.

Four, the shortcomings of piston compressor

1, the speed is not high, the machine is large and heavy;

2, complex structure, more vulnerable parts, large maintenance;

3, exhaust discontinuous, resulting in air pulsation;

4. Large vibration during operation.

Five, piston refrigeration compressor classification

(1) According to the sealing method can be divided into open type, semi-closed, fully closed three kinds.

The power input end of the crank shaft of the open-type compressor extends out of the body and is connected to the motor through a transmission device. The heat generated during compression is not transmitted to the motor, which is advantageous for large compressors to prevent the motor from overheating. The refrigerant also does not touch the motor coil, which is suitable for ammonia, which has a corrosive effect on copper. Therefore, ammonia refrigeration compressors in large and medium-sized food freeze-drying machines are all open-type, and the disadvantage of open-type compressors is that refrigerant may leak through the shaft of the compressor extending out of the housing.

The semi-enclosed compressor is to connect the compressor and the auxiliary motor with removable bolts in the same body, sharing a spindle, and can not use the shaft seal device to reduce the possibility of leakage. The low-temperature refrigerant vapor inhaled by this model often passes through the motor first, which can reduce the temperature rise of the motor, which is good for improving the life of the machine. In addition, the noise is lower. This type of freeze-drying machine is commonly used in the production of medicine.